What “fresh” means for premium baklava

Freshness shows up as: crisp layers, clean butter aroma, bright pistachio color, and balanced syrup (not sticky, not dry).

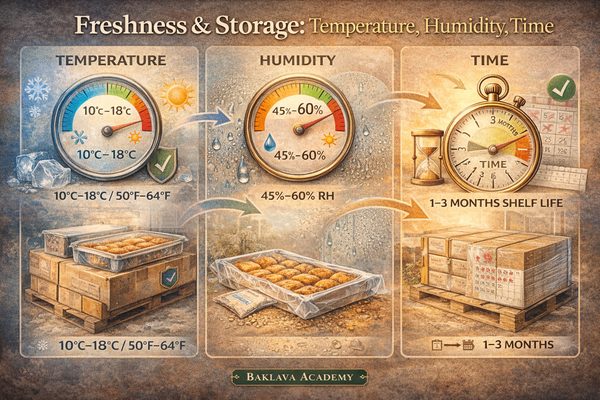

Key takeaways

- Heat spikes accelerate oil migration and aroma loss; stability matters more than “cold.”

- Humidity swings reduce crunch and can create condensation events that damage texture.

- Time is a logistics variable: plan shelf life backward from shelf date, not production date.

On this page

1) Temperature: stability beats extremes

Temperature impacts baklava in two main ways: it changes how fats behave (softening → movement) and how fast aromas fade. The goal is avoid heat spikes and avoid repeated warm/cool cycles.

- Don’t pack warm product: seal only after product is cooled to a stable internal temperature.

- Protect during handoffs: airports, docks, and last-mile terminals can be hotter than expected.

- Keep away from heat sources: sunlight, heaters, hot warehouse zones, truck walls.

If your destination climate is hot or you expect long dwell times, consider route strategy: see Cold Chain or Ambient?

2) Humidity: crunch protection + condensation prevention

Humidity is the biggest reason baklava loses crunch. Even with great product, moisture pickup can soften layers and make syrup feel “heavier.”

Avoid the two common humidity failures

- Slow humidity exposure: weak seals or poor barriers let moisture in over time.

- Condensation events: cold-to-warm transitions create droplets inside packaging.

- Barrier packaging: use inner materials that resist moisture pickup and seal reliably.

- Keep sealed during acclimation: if moving from cold to warm, do not open packs until they reach room temperature.

- Desiccant (where suitable): for long routes, humidity control can help—use food-safe packs and correct sizing.

3) Time: plan backward from the shelf date

Export “freshness” is won in planning. The best practice is to start from the required on-shelf date and work backward through:

- inbound transport + customs clearance

- warehouse receiving and QA

- retail distribution

- promotional window (if any)

Then set production and dispatch timing to preserve the highest quality window for the customer.

4) Warehouse & retail handling (often overlooked)

- Store off the floor: pallets/shelving reduce humidity exposure and accidental heat zones.

- Odor control: baklava absorbs odors—keep away from spices, chemicals, and strong-smelling products.

- FIFO discipline: rotate by production date and lot code; track holds and temperature incidents.

- Display guidance: avoid direct sun or hot lighting on retail shelves.

Storage checklist (copy/paste)

- Keep cartons in a cool, dry, stable area (avoid heat spikes).

- Maintain humidity control; avoid damp zones and open doors near rain/sea air.

- Do not open inner packs until ready to use/sell (minimize air exposure).

- If arriving from cold storage, acclimate sealed to prevent condensation.

- Keep away from odors (spices/chemicals) and direct sunlight.

- Follow FIFO by production date + lot codes; record any incidents.

FAQ

What ruins baklava fastest in transit?

Heat spikes and humidity swings—especially when combined with weak barrier packaging or repeated handoffs.

Should baklava be refrigerated?

It depends on route and storage conditions. Cooler temperatures can extend freshness, but condensation risk must be managed. If refrigerated, keep sealed until it reaches room temperature before opening.

How do we keep crunch longer?

Strong moisture barriers, stable storage conditions, and avoiding condensation events do more than any single “trick.” For packaging tactics, see Export Packaging.

Related: Syrup Science • Export Packaging • Cold Chain or Ambient?