Common Production Defects and How to Fix Them

Baklava Academy • Article 48 • Updated guide for importers, retailers, and hospitality brands.

Key takeaways

- Most defects are “systems problems,” not one-off mistakes. Fix the process variable (temperature, time, weight, moisture), not the symptom.

- Moisture balance is everything. Layer crispness depends on bake level, syrup consistency, cooling, and packaging.

- Consistency beats artistry for export. If you can’t repeat the result across batches, you can’t scale for international buyers.

- Document, measure, and standardize. Weigh key inputs, standardize syrup and butter handling, and track bake color and cooling time.

- Build a defect “decision tree.” Each defect should map to a short list of root causes with a fast corrective action.

Table of contents

- What “premium” looks like (a quick standard)

- The 6 root causes behind most defects

- Defects library: symptoms → causes → fixes

- Process controls that prevent defects

- Export-focused QA checks and sampling

- FAQ

What “premium” looks like (a quick standard)

Use this simple premium standard to judge batches quickly. If you can train your team to score these consistently, defects become easier to catch early—before packaging and export.

- Texture: crisp layers with clean bite; no gumminess; no dry “paper” top.

- Syrup balance: sweet but not heavy; no pooling; no crystal crunch; no wet tray.

- Aroma: clean butter aroma; fresh nut note; no rancid/oily smell.

- Appearance: even golden bake; defined layers; uniform cuts; bright pistachio or clean walnut look.

- Integrity: pieces hold shape; minimal breakage; stable in tray; no leaking oil stains.

Related Academy reads: Syrup Science • Clarified Butter • Quality Assurance

The 6 root causes behind most defects

Before we list individual defects, it helps to know the usual suspects. In real production environments, most problems trace back to these variables:

- Moisture imbalance: under-bake, syrup too heavy, humid cooling, or poor packaging venting.

- Temperature control: butter too hot/cold, syrup temperature mismatch, oven hot spots.

- Time control: inconsistent rest times, bake times, cooling times, or syrup soak times.

- Weight control: variable nut fill weight, butter dosage, syrup volume per tray.

- Raw material variation: flour strength, yufka thickness, butter quality, pistachio moisture/grade.

- Handling/compression: rough cutting, stacking pressure, early packaging, and transport vibration.

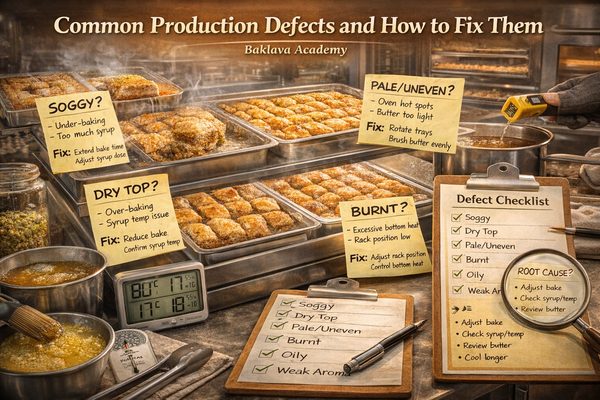

Defects library: symptoms → causes → fixes

Use this section like a troubleshooting manual. Start with the symptom you see, then check the listed root causes in order. Apply “fast fixes” immediately, then add the prevention control so it doesn’t return next week.

1) Soggy layers / lost crunch

Symptoms: soft bite, wet tray, layers merge, syrup feels heavy.

- Most likely causes: under-bake; too much syrup; syrup too warm at pour; humid cooling area; packaging too early (traps steam).

- Fast fixes: extend bake to proper color; reduce syrup dose slightly; cool longer before packaging; cover/vent appropriately.

- Prevention controls: standardize bake color target; weigh syrup per tray; define cooling time before sealing.

2) Dry top layers / “paper” texture

Symptoms: top shatters, dull bite, less aroma, top looks faded.

- Most likely causes: over-bake; low syrup absorption due to syrup too cool/too thick; exposure to dry airflow; long holding without cover.

- Fast fixes: adjust bake down; ensure correct syrup preparation; reduce airflow exposure during cooling.

- Prevention controls: bake timing + color standard; syrup consistency SOP; covered cooling racks when environment is dry.

3) Syrup pooling at the bottom

Symptoms: liquid syrup collects, bottom becomes overly sweet/wet, tray looks “flooded.”

- Most likely causes: too much syrup; insufficient bake structure; cut pattern blocks absorption; tray too deep or compressed layers.

- Fast fixes: reduce syrup volume; improve bake; ensure correct cut depth before baking so syrup pathways exist.

- Prevention controls: dose syrup by weight; standardize cut depth/spacing; document tray dimensions and fill height.

4) Syrup crystallization (grainy sugar)

Symptoms: crunchy sugar crystals, cloudy syrup, gritty bite.

- Most likely causes: over-concentrated syrup; contamination (sugar crystals on ladle); excessive agitation; uneven cooling; inconsistent batch reboil.

- Fast fixes: make a fresh batch; clean tools; avoid aggressive stirring once dissolved; store syrup cleanly.

- Prevention controls: syrup SOP (consistent concentration); dedicated clean utensils; no “topping up” old syrup without control.

5) Pale color / uneven browning

Symptoms: light bake, patchy color, dull appearance, weak roasted notes.

- Most likely causes: oven hot spots; insufficient preheat; tray loading pattern; butter application uneven; dough thickness variation.

- Fast fixes: rotate trays; confirm preheat; improve butter brushing distribution; check yufka thickness consistency.

- Prevention controls: oven mapping; standard loading plan; butter application SOP; supplier spec for dough thickness.

6) Burnt bottom / bitter finish

Symptoms: dark base, bitter notes, overly toasted aroma, hard base.

- Most likely causes: excessive bottom heat; tray material too conductive; oven rack position too low; sugar/butter burning.

- Fast fixes: adjust rack position; reduce bottom heat exposure; change tray spec or use insulation sheet where appropriate.

- Prevention controls: tray standardization; rack position SOP; bake curve log (time + visual color checks).

7) Greasy mouthfeel / oily tray

Symptoms: oily taste, fat pooling, packaging stains, heavy texture.

- Most likely causes: excess butter; butter applied at wrong temperature; low-quality fat separating; under-bake keeps moisture trapped (drives oil migration later).

- Fast fixes: reduce butter dose; apply at correct working temperature; bake to proper structure; review butter quality.

- Prevention controls: weigh butter usage per tray; clarified butter SOP; incoming butter QC (aroma, cleanliness).

8) Cracked top / broken layers

Symptoms: top cracks, flakes detach, pieces break when lifted.

- Most likely causes: dough too dry; insufficient butter between layers; rough handling; over-bake; cutting with blunt tools.

- Fast fixes: improve butter distribution; handle with better support; sharpen blades; adjust bake down slightly.

- Prevention controls: blade maintenance; handling SOP; dough humidity management in production room.

9) Shrinking, warping, or lifting corners

Symptoms: corners lift, pieces warp, tray gaps appear after bake.

- Most likely causes: dough tension from stretching; uneven moisture; uneven butter; oven airflow; incorrect rest time.

- Fast fixes: allow proper resting; avoid over-stretching; improve even layering; ensure stable dough handling conditions.

- Prevention controls: standardized layering method; rest time SOP; control room humidity to reduce drying during assembly.

10) Uneven cuts / ragged edges

Symptoms: messy edges, inconsistent portion size, poor presentation, higher breakage.

- Most likely causes: dull knives; inconsistent cut depth; tray movement; cutting too late/too early; mismatched cut pattern for format.

- Fast fixes: sharpen blades; standardize cut depth; stabilize tray; train on the correct cut map.

- Prevention controls: cut SOP with a measured grid; blade schedule; portion spec sheet for every SKU.

11) Weak pistachio aroma / muted flavor

Symptoms: “flat” taste, less nut aroma, premium perception drops.

- Most likely causes: pistachio grade too low; pistachio stored warm/long; oxidation; over-roasting; dominant syrup sweetness.

- Fast fixes: upgrade pistachio grade; ensure correct storage; adjust syrup balance so nuts shine.

- Prevention controls: incoming nut QC; pistachio storage SOP; batch tasting panel with scoring sheet.

12) Rancid or off aromas

Symptoms: “stale oil” smell, waxy notes, unpleasant aftertaste.

- Most likely causes: fat oxidation (butter/nuts); poor storage; exposure to heat/light; long holding before sealing; contaminated storage areas.

- Fast fixes: remove affected stock; review ingredient freshness; improve storage and packaging barrier.

- Prevention controls: supplier approval; strict FIFO on ingredients; sealed storage; temperature stability through production and packing.

Related: Gaziantep Pistachios 101 • Butter Quality • Production Defects

Process controls that prevent defects (the “boring” part that makes you money)

Export buyers don’t just want a great tray—they want repeatability. The easiest way to reduce defects is to control the few variables that create most variation.

A) Standardize by weight (not “by eye”)

- Nut fill weight per tray / per piece (define a tolerance range).

- Butter dose per tray (track usage and variance).

- Syrup dose per tray (weigh, don’t guess).

B) Build 3 SOPs and enforce them

- Dough & layering SOP: thickness control, rest times, handling environment.

- Bake SOP: preheat, rack position, rotation timing, target color standard.

- Syrup SOP: consistent preparation, clean tools, controlled pouring and cooling timeline.

C) Add simple QC checks to every batch

- Visual: uniform cut map, consistent bake color, clean edges.

- Weight: random check 10 pieces for portion consistency.

- Texture: bite test after cooling, then again after 12–24 hours.

- Packaging integrity: tray fit, movement test, barrier seal check.

Export-focused QA checks and sampling (what buyers should request)

If you’re an importer or retailer, you can prevent surprises by sampling smartly and requesting the right documentation. Quality issues often show up after time—so test against your real route and real shelf life.

What to ask for in every order

- Production date and batch/lot identification.

- Ingredient list + allergens (nuts, dairy, gluten; and cross-contact statement where relevant).

- Packaging specification (tray type, barrier film, carton strength) for your route.

- Storage guidance aligned with your retail reality.

Practical sampling protocol (simple but effective)

- Arrival check: inspect trays for breakage, oil stains, or condensation signs.

- Day 0 taste: score aroma, crunch, sweetness, nut intensity.

- Day 3–7 check: repeat scoring to see texture drift.

- Retail simulation: open/close package daily (mimics display exposure) and re-score.

Related: Shelf-Life Testing • Export Packaging • How to Read a COA

FAQ

What’s the fastest way to reduce defects across batches?

Standardize by weight (nut fill, butter dose, syrup dose) and enforce three SOPs: layering, baking, and syrup preparation. Most “mystery” defects disappear when you control those variables.

Which defect causes the most export complaints?

Texture drift—especially softness from humidity exposure and temperature swings. If the product is excellent on Day 0 but soft later, review packaging barrier, sealing timing, and route conditions.

How do I choose packaging to reduce defect risk?

Match the packaging system to your route: movement protection (trays/inserts), humidity barrier (films/seals), and carton strength. For slower retail turnover, sealed packs usually outperform open trays on consistency.

Need help building defect-proof export batches?

If you’re shipping internationally, consistency is the product. Tell us your destination, shelf-life targets, and preferred formats. TBC A.S. can recommend export-ready SKUs, packaging systems, and QA checkpoints aligned to your route.